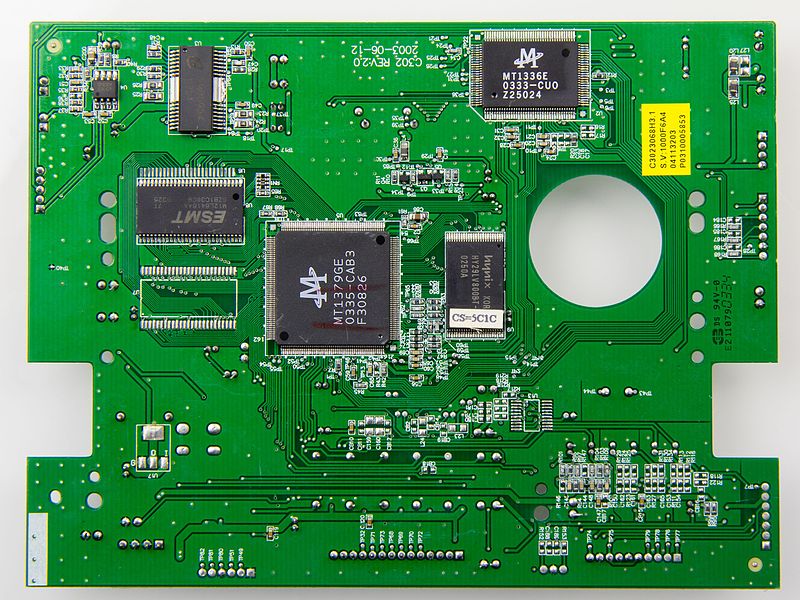

Prototyping is an essential step in the development and design of printed circuit boards (PCBs). Not only does it ensure that all components are working as expected, but it also allows designers to identify potential issues with their designs before they move into production.

By creating prototypes and testing them out in a controlled environment, engineers can quickly adjust their designs based on feedback from users or other stakeholders, ensuring that any problems have been addressed before committing to production. In this article, we will explore why prototyping is so important for PCBs and how it helps creators get the most out of their work.

Overview of Prototyping for PCBs

Prototyping is an important part of the PCB development and design process. It allows engineers to create and test a working model before committing resources to full production.

Through prototyping, potential problems can be identified early in the process, saving time and money that would have otherwise been wasted on faulty designs or processes. Prototypes also provide valuable feedback for improvements, which can drive further innovation in PCBs.

The need for accurate prototypes has led to the development of specialized tools such as 3D printers, CNC machines, etching systems, and CAD software packages that all help streamline the prototyping process. These tools allow engineers to quickly produce accurate models from their designs with minimal effort or cost compared with traditional manufacturing methods.

Additionally, rapid prototyping techniques enable shorter product cycles due to their efficient turnaround times between iterations of a prototype design; this ultimately leads to improved products being delivered faster than ever before. In conclusion, proper use of prototyping during PCB development and design is essential for successful outcomes since it offers numerous benefits including reduced costs and improved accuracy/efficiency during production stages later on down the line – particularly when used in combination with modern technologies like 3D printing and CAD software packages available today!

Benefits of Utilizing a Prototype in PCB Development

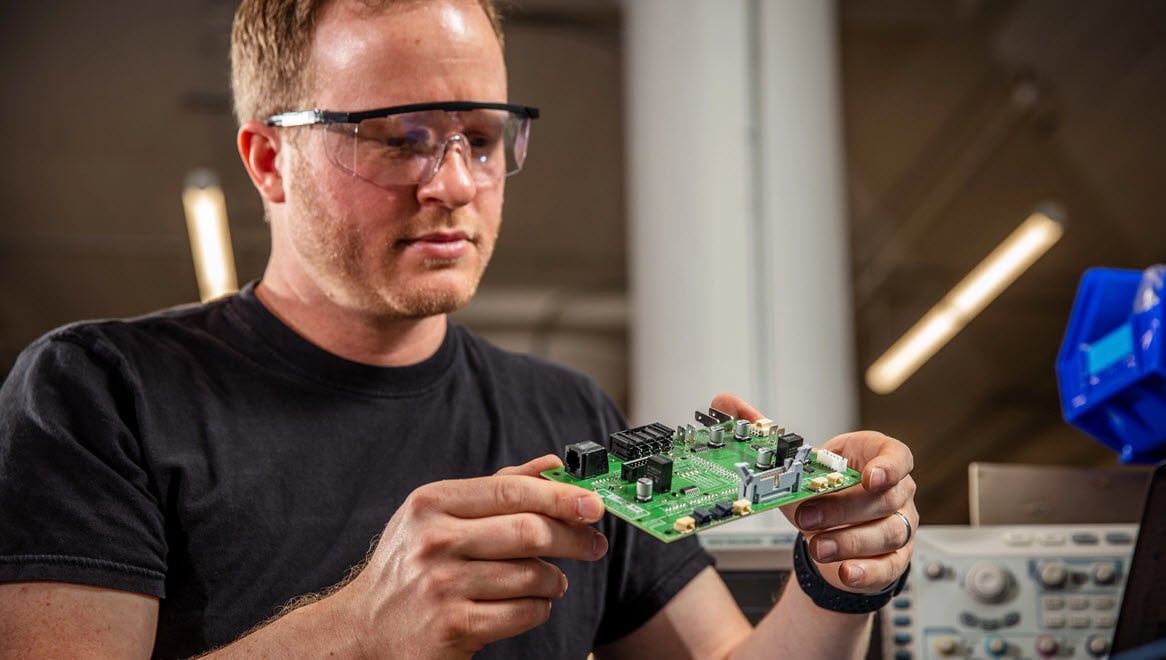

The use of a prototype in PCB development and design is incredibly vital for ensuring the end product works as desired. By testing out a model first, any potential problems can be identified and addressed before they cause significant delays or damages further down the line.

Here are some key benefits of utilizing prototypes: 1. Cost savings – This type of pre-testing allows designers to make changes quickly and inexpensively during the initial stages, avoiding costly mistakes later on.

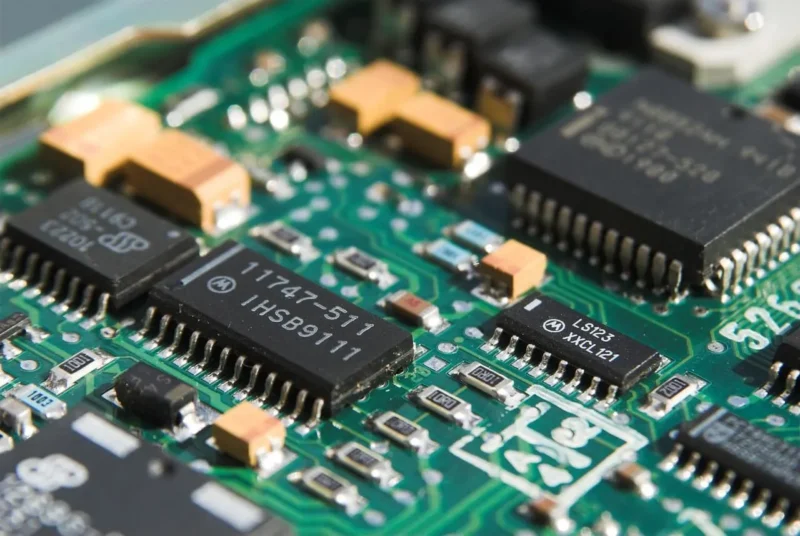

2. Improved accuracy – With a physical prototype, it\’s easy to test out various components and check that all parts fit together correctly without any interference issues arising from inaccurate measurements or incorrect component placement.

3. Faster production – A completed prototype makes it easier for manufacturers to get started on production as soon as possible with less risk of error or delay due to unforeseen technical issues.

4. Better quality assurance– With prototyping in place, there’s more opportunity for thorough testing throughout the process so that you can ensure your final product meets even the highest standards of quality control.

Best Practices for Creating an Effective Prototype

Creating an effective prototype is key to a successful PCB development and design process. Here are some best practices for crafting the perfect prototype: 1.

Start by researching existing PCB designs that meet your requirements and use them as inspiration for yours. This will save you time in prototyping and give you ideas on what components to include in your design; 2.

Create a virtual model of the circuit board before physically constructing it, using computer-aided design software such as Altium Designer or KiCad; 3. Consider building multiple prototypes with different approaches so you can compare which yields better results; 4.

Try out various materials when constructing the actual prototype, such as FR-4 fiberglass boards or aluminum substrates, to find out which works best for your application; 5. Use quality components that have been tested for reliability, especially if you are designing products that require long life cycles or extreme environmental conditions; 6.

Utilize testing tools like oscilloscopes and logic analyzers during the prototyping phase so any issues can be identified early on; 7. When debugging issues related to signal integrity or power integrity create simulations with specialized tools like HyperLynx Signal Integrity Analyzer from Mentor Graphics’s PADS suite of products if necessary; 8 Finally make sure you document thoroughly every step of the way – this will save valuable time should something go wrong during production later down the line!

Common Challenges Faced During Prototyping Processes

When working on prototyping processes for PCB development and design, it is important to be aware of the common challenges that can arise. One of these is ensuring that all components are correctly placed and connected throughout the entire process.

This can require careful planning ahead of time to ensure everything fits into its proper place. Additionally, there is a need for accuracy when routing traces between components as any flaws could lead to an unreliable or malfunctioning product in the end.

Furthermore, adherence to complex specifications laid out by clients or manufacturers needs to be taken into account and respected during the prototype-building phase. Testing also plays a crucial role in making sure that all components are functioning properly, which requires additional resources such as specialized equipment, personnel with expertise in testing procedures, etc.

, adding another layer of complexity to the whole process. Lastly, depending on individual projects and their requirements there may be other challenges faced during prototyping processes which should not be overlooked if true success is desired from each project undertaken.

Conclusion

Prototyping is an essential step in the development and design of printed circuit boards (PCBs). It allows designers to test their ideas quickly and inexpensively before committing to a large-scale production cycle.

By creating prototypes, engineers can identify potential issues early on that might otherwise cause costly delays or even permanent damage down the line. One technology that has made prototyping easier for PCBs is Castellation PCB Technology, which utilizes multiple layers of copper material to create complex designs with less time and resources than traditional methods. With its help, PCB designers can create better products faster while saving money on manufacturing costs.

In conclusion, prototyping is key to efficiently developing high-quality printed circuit boards; leveraging technologies like Castellation PCB Technology can make it easier.