The aerospace and defense industries require rigorous testing for their products. To meet these requirements, environmental testing chambers are essential tools. These specialized chambers provide precise temperature, humidity, and pressure controls to ensure the safety of the product being tested.

With a range of sizes and configurations available, they can simulate a wide variety of environments from extreme cold or hot temperatures to high altitudes and vibration levels.

As technology advances, so too do the capabilities of environmental test chambers; allowing them to replicate increasingly complex scenarios to guarantee quality assurance standards are met. As such, they play an invaluable role in providing reliable performance data for some of the world’s most important projects.

Design Considerations for Aerospace and Defense Applications

Design considerations for Aerospace and Defense Applications are crucial in ensuring that the environmental testing chambers used meet exact requirements. Many factors, including safety regulations, must be taken into account when designing these chambers.

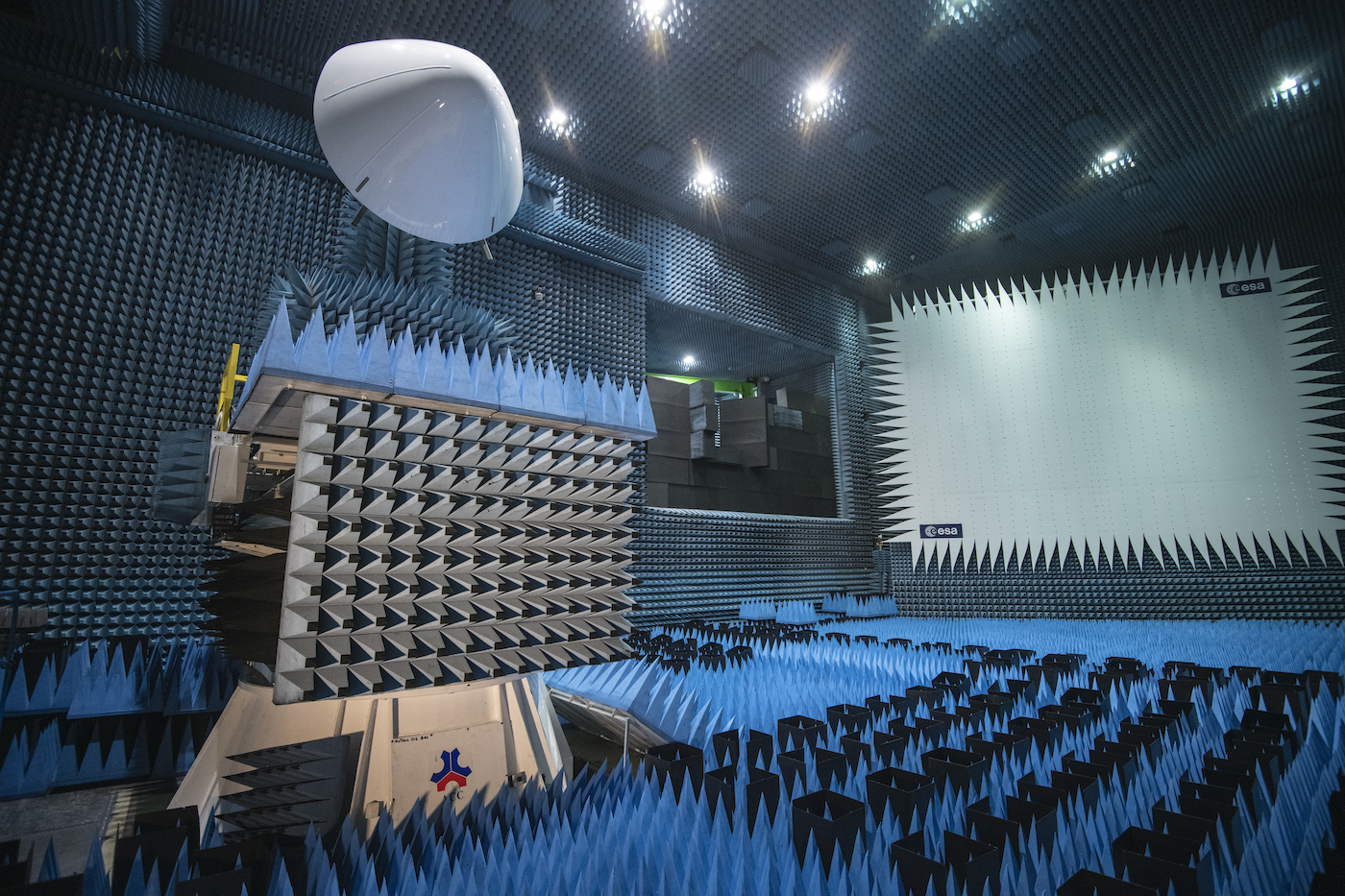

The chamber’s interior design should accommodate all necessary components while also providing a safe environment for personnel to work in during testing. Additionally, temperature and humidity control should allow for uniformity across multiple tests without compromising results or damaging the equipment being tested.

Consideration should also be given to soundproofing the facility as noise can interfere with test results as well as create an uncomfortable workspace.

Furthermore, dust-free environments may be needed to ensure the optimal functioning of delicate components during testing procedures. Finally, proper filtration methods must be put in place so sensitive instruments remain free from airborne contaminants that could cause inaccurate readings or damage the devices altogether.

With careful thought and consideration given to each of these elements, aerospace and defense applications will benefit from reliable environmental testing chambers designed specifically for their needs

Safety Features for Aerospace and Defense Testing Chambers

When it comes to Aerospace and Defense testing chambers, safety is an absolute priority. Many of these environments require precision control over temperature, pressure, and humidity levels. To ensure the protection of personnel and equipment, environmental test chambers must have sophisticated features that help mitigate potential risks.

One such feature is a robust alarm system to alert operators when critical parameters are exceeded or if any irregularities occur during tests.

Other features include door locks for secure access; explosion-proof lighting fixtures; reinforced walls with special coatings; fire suppression systems; emergency shutoff valves for gas lines; smoke detectors in areas prone to chemical spills or fire hazards; and redundant power sources to prevent unexpected shutdowns.

All of these technologies work together to provide maximum safety while conducting Aerospace and Defense tests within a controlled environment.

Benefits of Utilizing Environmental Test Chambers in the Aerospace and Defense Industries

Environmental test chambers are an essential tool for the aerospace and defense industries as they provide a controlled environment to accurately simulate various conditions that aircraft and other military equipment may be exposed to in their future operations. The benefits of utilizing these chambers include increased safety, reliability, quality assurance, cost savings, and improved performance. Using environmental test chambers allows designers and engineers to ensure the optimal performance of any product or system before it is deployed in the field.

This helps prevent costly repairs or replacements due to malfunctioning parts after deployment. Additionally, testing can be conducted under multiple scenarios with different parameters being adjusted depending on the needs of the project. This ensures products are properly calibrated before entering production which reduces maintenance costs significantly over time. Test chambers help reduce risk by allowing for safe testing environments that otherwise would not be possible in real-life situations.

By simulating extreme temperatures, humidity levels, dust particles, etc., aerospace and defense sectors can confidently deploy systems knowing they have been thoroughly tested against all potential risks beforehand.

Furthermore, these tests can help identify areas where improvements need to be made for designs to meet necessary standards before reaching public use including those mandated by governmental regulations.

In conclusion, environmental test chambers offer immense advantages when it comes to designing products used within Aerospace & Defense fields such as increased safety, reliability, quality assurance, cost savings & improved performance.

They allow companies within this sector to cut down on expenses while creating more efficient & reliable products associated with their industry

Conclusion

In conclusion, environmental testing chambers for aerospace and defense applications are a crucial component of ensuring the safety and reliability of equipment and systems in extreme conditions.

With an ever-growing demand for increased performance and efficiency, these chambers provide invaluable insights into how various components function within their intended environment.

In addition to offering greater confidence in the quality control process, they also help reduce costs associated with maintenance or repair due to malfunctioning parts. Ultimately, environmental testing chambers offer robust solutions for reliable operation even when faced with the most challenging environments imaginable.